Aplix Manufacturing Corporation

Charlotte, NC

1981

Charlotte, NC

1981

Industrial buildings of this type are to be found across the country. In response to the imperatives of cost. speed of construction and expandability, they abound as unmemorable images, anonymous and scaleless combinations of metal panel or double-tee skins plopped on their sites, the office component a bump on the front of the "pickle".

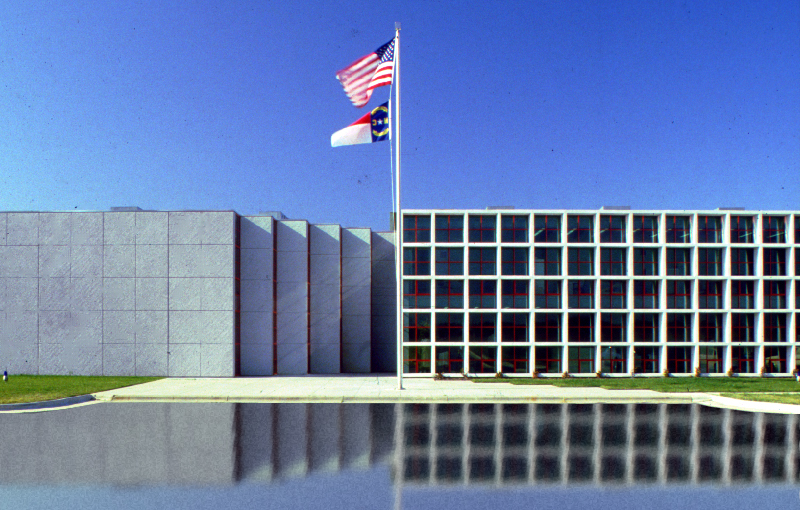

This project proposes an alternative. Built on a fast track program within a very constrained budget, it seeks to create a calm and restrained presence with simple materials carefully chosen, thoughtfully assembled.

A great circle was incised in this gently sloping site, functionally to induce drainage away from the building, visually to create a sense of place in an otherwise unremarkable site. A double row of Lombardy Poplars outlines the circle. The trees will one day provide a powerful unifying gesture between the building and the land.

The exterior skin of the manufacturing area is of precast 8' x 20' panels scored into 4' squares in gray concrete with a white aggregate. There is a diagonal striation in the panel and the resulting rib is fractured to expose the white aggregate. The panel fabricators set tip a special jig to mass-produce the panels very economically. The total building height is established by the high-bay requirements of the manufacturing operation and results in a dimension of 20' from the finished floor to the top of the parapet.

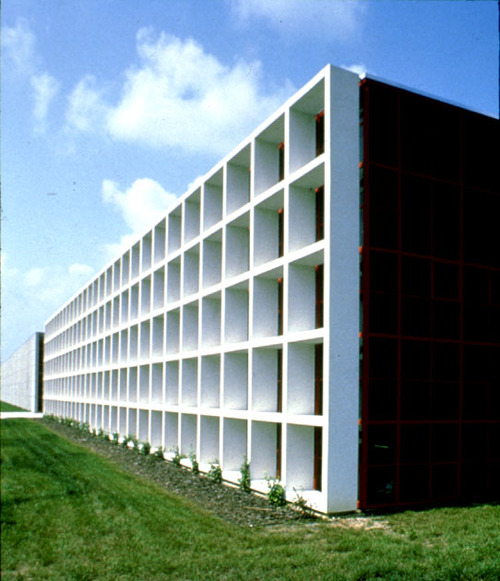

In the office block in the northeast corner of the buildings two levels of office space were sandwiched into the 20" height of the manufacturing plant. By exposing the steel structure and the metal deck, an illusion of added height is created in the offices even within the limited floor to floor dimensions. Green tinted insulated glass covers three sides of the office block. A freestanding sun-screen shades the eastern side and Jasmine has been planted at the base to climb it as a trellis. The two story space continues to the northeastern edge and will provide an easy means for projected office expansion. Also located on the northeastern side of the building is a staging area for the shipping operation.

All of the structure in both the office and warehouse is carefully articulated to coordinate with the total geometry of the modularly organized building and its lighting, HVAC and sprinkler systems Air cooling and heating are accomplished by units located on the top of the roof. These units condition the air on the second level by creating an air wall between the office and the corridor. The office areas on the first floor are conditioned by the exposed outlets in the ceiling occurring on a line beneath the air wall.

The entire west wall of the building is removable to accommodate the predicted future expansion. The window openings in the manufacturing area are high and relatively small because of the significant security issue having to do with the manufacturing process of the client. Large scuppers allow water to flow off the eastern edge of the roof in lieu of internal roof drains. An economic necessity, the scuppers nevertheless, coupled with tile small windows at regular intervals set tip a rhythm that adds a pleasant elaboration to the simple western facade.

Awards

1981 NORTH CAROLINA AIA HONOR AWARD